1. Upgrading to Maximo 7.6.1

IBM has announced end of support for Maximo 7.6.0 as of September 30, 2021. If you haven’t yet upgraded to Maximo 7.6.1, this is a perfect opportunity to begin planning your upgrade so that you can take advantage of new features and continue to receive support for your EAM system.

2. Moving to the Cloud

By using Maximo in the cloud, you can focus on your business rather than the technical details of maintaining a Maximo system. Your SaaS provider manages upgrades, availability, security, backup, disaster recovery, and licensing, to name a few key benefits. As IT departments are continually stretched thinner and are expected to do more with less each passing year, it makes sense to partner with an organization that is focused exclusively on Maximo.

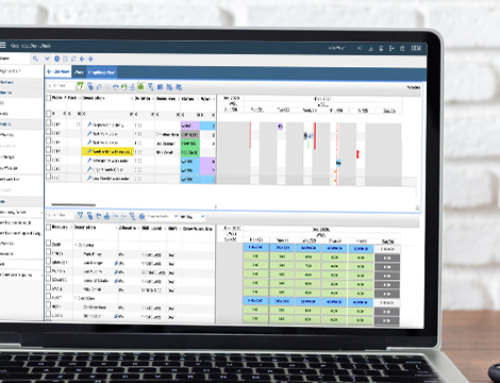

3. Creating High-Impact Dashboards and Reports

If you have been using Maximo for some time, you likely have a wealth of maintenance and reliability data in your system. Are you able to access it on demand, or do you need to manually compile reports each time information is requested? Maximo includes robust reporting capabilities. In addition to BIRT and ad-hoc reporting, you are entitled to use IBM Cognos dashboards to rapidly provide visual insights to your users. Our clients have found that, once Maximo-Cognos integration is configured, they can rapidly create their own dashboards without requiring niche technical skills.

4. Improving Data Quality

Your EAM system is only as valuable as the data it contains. We recommend selecting one or two key areas at a time, focusing and improving your EAM program incrementally. For example, would you like to improve your ability to spot trends in equipment failures so that you can take appropriate proactive measures? If so, you may wish to review and update your organization’s failure codes so that you can leverage your work order history. Similarly, you may find that you are collecting lots of detail on your work orders, but is it the right information to assess and improve reliability? Feel free to contact us if you’d like feedback and recommendations to improve the quality of your EAM data.

5. Using IoT to Reduce Downtime and Cut Costs

You likely already have many interconnected IoT devices monitoring your equipment. By harnessing that data and utilizing condition-based maintenance, you can identify potential issues while they are minor – before they lead to breakdowns and downtime. Further, you may be able to use condition-based maintenance to reserve filter and fluid changes for when they are necessary, rather than adhering to an arbitrary time-based schedule.